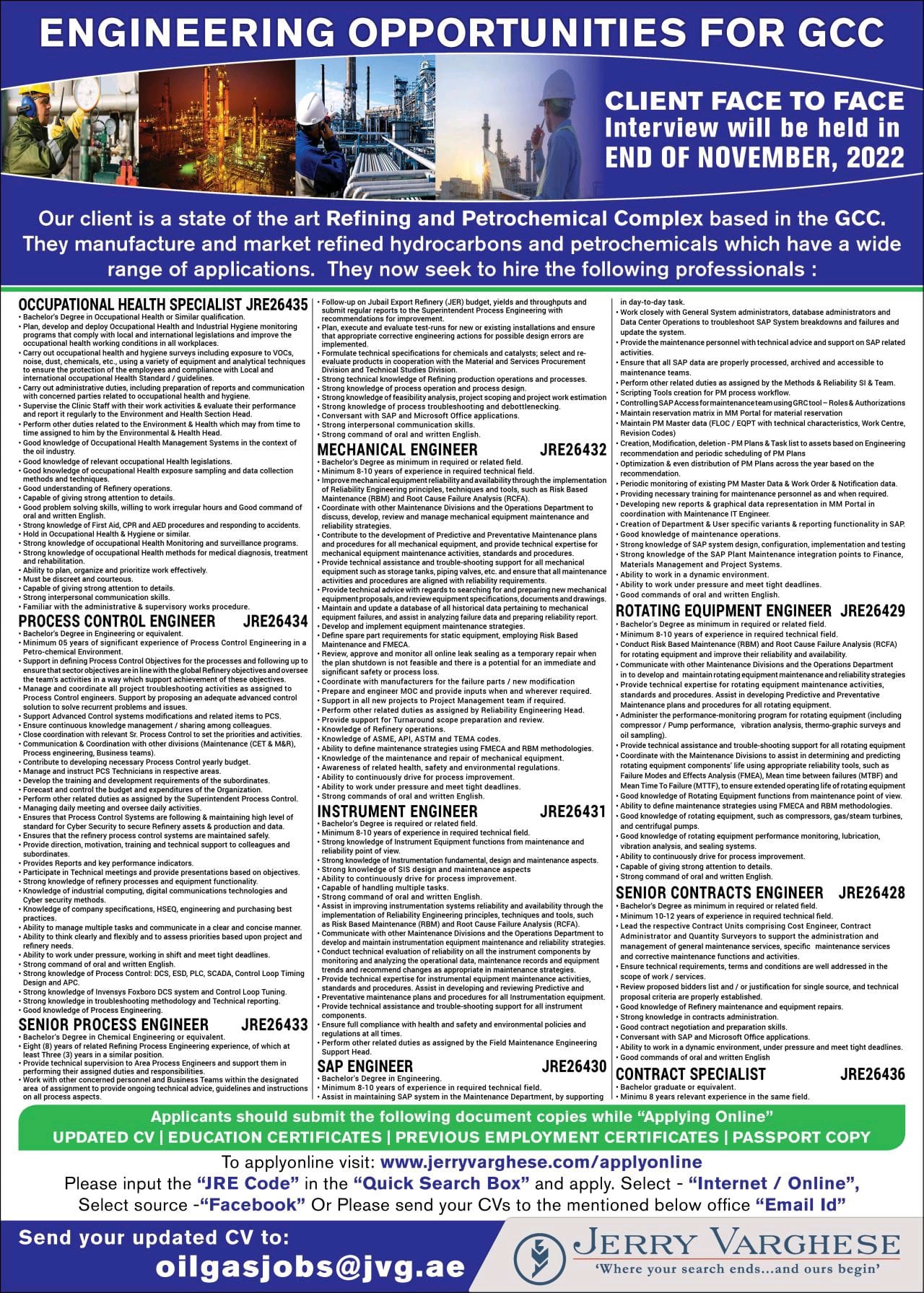

ENGINEERING OPPORTUNITIES FOR GCC

CLIENT FACE TO FACE

Interview will be held in

END OF NOVEMBER, 2022

Our client is a state of the art Refining and Petrochemical Complex based in the GCC.

They manufacture and market refined hydrocarbons and petrochemicals which have a wide

range of applications.

OCCUPATIONAL HEALTH SPECIALIST JRE26435

• Bachelors Degree in Occupational Health or Similar qualification.

• Plan, develop and deploy Occupational Health and Industrial Hygiene monitoring

programs that comply with local and international legislations and improve the

occupational health working conditions in all workplaces.

• Carry out occupational health and hygiene Surveys including exposure to VOCS,

noise. dust, Chemicals, a variety Of equipment and techniques

to ensure the protection of the employees and compliance with Local and

international occupational Health Standard / guidelines,

• Carry out administrative duties, including preparation of reports and communication

With concerned parties related to occupational health and hygiene,

• Supervise the Clinic Staff with their vork activities & evaluate their performance

and report it regularly to the Environment and Health Section Head.

• perform Other duties related to the Environment & Health Which may to

time assigned to him by the Environmental Health Head.

• Good knowledge of Occupational Health Management Systems in the context of

the oil industry.

• Good knowledge of relevant occupational Health legislations.

• knowledge of occupational Health exposure sampling and data collection

methods and techniques.

• Good understanding of Refinery operations.

• Capable of giving strong attention to details.

• Good problem solving Skills. Willing to work and Good command Of

oral and written English.

• Strong knowledge of First Aid, CPR and AED procedures and responding to accidents

• Hold in Occupational Health & Hygiene or

• Strong knowledge of occupational Health Monitoring and surveillance programs.

• Strong knowledge Of occupational Health methods dlagnosis, treatment

and rehabilitation.

• Ability to plan. Organize and prioritize work effectively.

• Must be discreet and courteous.

• Capable Of giving Strong attention to details,

• Strong interpersonal communication skille

• Familiar with the administrative supervisory works procedure.

PROCESS CONTROL ENGINEER

JRE26434

• Bachelors Degree in Engineering or equivalent,

• Minimum OS years of significant experience of Process Control Engineering in a

petro-chemical Environment.

• Support in denning Process Control Objectives for the processes and following up to

ensurethat sector objectives are In line with the global Refinery objectives and oversee

the team’s activities a way which support achievement of these objectives.

• Manage and coordinate all project troubleshooting activities as assigned to

Process Control engineers. Support by proposing an adequate advanced control

solution to solve recurrent problems and issues.

• Support Advanced Control systems modifications and related items to PCS.

• Ensure continuous knowledge management Sharing among colleagues.

• Close coordination with relevant Sr Process Control to set the priorities and activities.

• Communication 8 Coordination with other divisions (Maintenance (CET & M&R),

process engineering. Business teams).

• Contribute to developing necessary Process Control budget.

• Manage and instruct PCS Technicians in respective areas.

• Develop the training and development requirements of the subordinates.

• Forecast and control the budget and expenditures Of the Organization,

• Perform other related duties as assigned by the Superintendent Process Control.

• Managing daily meeting and oversee daily activities.

• Ensures that Process Control Systems are following maintaining high level of

Standard for Cyber Security to Secure Refinery assets & production and data,

• Ensures that the refinery process control systems are maintained safely

• Provide direction, motivation, training and technical support to colleagues and

subordinates.

• provides Reports and key performance indicators.

• Participate in Technical meetings and provide presentations based on objectives.

• Strong knowledge Of refinery processes and equipment functionality.

• Knowledge of industrial digital communications and

Cyber security methods

• Knowledge of company specifications, HSEQ, engineering and purchasing best

practices

• Ability to manage multiple tasks and communicate in a Clear and concise manner.

• Ability to think clearly and flexibly and to assess priorities based upon project and

refinery needs.

• Ability to work under pressure, in Shift and meet tight

• Strong command Of oral and written EngllSh.

• Strong knowledge of Process Control: DCS, ESD, PLC. SCADA, Control Loop Timing

Design and APC.

• Strong knowledge of Invensys Foxboro OCS System and Control Loop Tuning.

• Strong in troubleshooting methodology and Technical reportlng_

• Good knowledge of Process Engineering.

SENIOR PROCESS ENGINEER

JRE26433

• Bachelor’s Degree in Chemical Engineering or equivalent.

• Eight (8) years of related Refining Process Engineenng experience, of which at

least Three (3) years a similar position.

• Provide technical supervision to Area Process Engineers and support them in

performing their assigned duties and responsibilities.

• Work With Other concerned personnel and Business Teams Within the designated

area Of assignment to provide ongoing technical advice, guidelines and instructions

on all process aspects

They now seek to hire the following professionals :

• Follow-up on Jubail Export Refinery (JER) budget, yields and throughputs and

Submit regular reports to the Superintendent process Engineering with

recommendations for improvement

• plan, execute and evaluate test-runs for or existing installations and

that appropriate corrective engineering actions for possible design errors are

implemented

• Formulate technical specifications for chemicals and select and re-

evaluate in With the Material and Services

Division and Technical Studies Division

• Strong technical knowledge of Refining production operations and processes.

• Strong knowledge of process operation and process design,

• Strong knowledge of feasibility analysis, project scoping and project work estimation

• Strong knowledge of process troubleshooting and debottlenecking.

• Conversant With SAP and Microsoft Office applications,

• Strong interpersonal communication skills.

• Strong command Of oral and written English,

MECHANICAL ENGINEER

• Bachelors Degree as minimum in required or related field.

JRE26432

• Minimum years Of experience in required technical

• Improve mechanical equipment reliability and availability through the implementation

of Reliability Engineering principles, and tools. such as Risk Based

Maintenance (RBM) and Root Cause Failure Analysis (RCFAb

• Coordinate with other Maintenance Divisions and the Operations Department to

discuss, develop, review and manage mechanical equipment

reliability strategies.

• Contribute to the development of Predictive and Preventative Maintenance plans

and procedures for all mechanical equipment, and provide technlcal for

mechanical equipment maintenance activities, standards and procedures.

• Provide technical assistance and trouble-shooting support for all mechanical

equipment such as Storage tanks. piping valves, etC_ and ensure that all maintenance

activities and procedures are aligned with reliability requirements.

• provide technical advice with regards to searching for and preparing mechanical

equipment and review equipment specifications, and drawings.

• Maintain and update a database of all historical data pertaining to mechanical

equipment failures, and assist in analyzing failure data and preparing reliability report,

• Develop and implement equipment maintenance strategies.

• Define spare pan requirements for static equipment, employing Risk Based

Maintenance and FMECA,

• Review, approve and monitor all online leak sealing as a temporary repair when

the plan shutdown is not feasible and there is a potential for an immediate and

Significant safety or process loss.

• Coordinate with manufacturers for the failure parts / new modification

• Prepare and engineer MOC and provide inputs when and wherever required.

• Support in all new projects to Project Management team if required.

• perform Other related duties as assigned by Reliability Engineering Head,

• Provide support for Turnaround scope preparation and review.

• Knowledge of Refinery operations.

• Knowledge of ASMÉ, API, ASTM and TEMA codes.

• Ability to define maintenance Strategies using FMECA and RBM methodologies.

• Knowledge of the maintenance and repair of mechanical equipment.

• Awareness of related health. safety and environmental regulations.

• Ability to continuously drive for process improvement

• Ability to work under pressure and meet tight deadlines.

• Strong commands of oral and written English,

INSTRUMENT ENGINEER

• Bachelor •s Degree is required Or related field,

• Minimum 010 years of experience in required technical field.

JRE26431

• Strong knowledge of Instrument Equipment functions from maintenance and

reliability point Of View,

• Strong knowledge Of fundarnental, design aspects.

• Strong knowledge of SIS design and maintenance aspects

• Ability to continuously drive for process improvement.

• Capable Of handling multiple tasks.

• Strong command of oral and written English.

• Assist in improving instrumentation Systems reliability and availability through the

implementation of Reliability Engineering principles, techniques and tools, such

as Risk Based Maintenance (RBM) and Root Cause Failure Analysis (RCFA)_

• Communicate With Other Maintenance Divisions and the Operations Department to

develop and maintain instrumentation equipment maintenance and reliability strategies

• Conduct technical evaluation of reliability on all the instrument components by

monitoring and analyzing the operational data, maintenance records and equipment

trends and recommend changes as appropriate in maintenance strategies.

• prcwide technical expertise for instrumental equipment maintenance activities,

Standards and procedures. Assist in developing and reviewing Predictive and

• Preventative maintenance plans and procedures for all Instrumentation equipment.

• provide technical assistance trouble-shooting support all instrument

componente

• Ensure full compliance with health and safety and environmental policies and

regulations at times,

• Perform other related duties as assigned by the Field Maintenance Engineering

in day-to-day task

• Work closely with General System administrators, database administrators and

Data Center Operations to troubleshoot SAP System breakdowns and failures and

update the system.

• Provide the maintenance personnel with technical advice and support on SAP related

activities.

• Ensure that all SAP data are properly processed, archived and accessible to

maintenance teams

• Perform other related duties as assigned by the Methods & Reliability SI & Team.

• Scripting Tools creation for PM process workflow

• Controlling SAPAccessformaintenanceteam using GRCtooI — Roles’ Authorizations

• Maintain reservation matrix in MM Portal for material reservation

• Maintain PM Master data (FLOC / EQPT with technical characteristics, Work Centre,

Revision Codes)

• Creation. Modification, deletion – PM Plans & Task list to assets based on Engineering

recommendation and periodic scheduling of PM Plans

• Optimization 8 even distribution of PM Plans across the year based on the

m m t ion

• Periodic monitoring of existing PM Master Data & Work Order & Notification data.

• Providing necessary training for maintenance personnel as and when required.

• Developing new reports & graphical data representation in MM Portal in

coordination with Maintenance IT Engineer.

• Creation of Department & user specific variants & reporting functionality in SAP.

• GCH)d knowledge of maintenance operations.

• Strong knowledge of SAP system design. configuration, implementation and testing

• Strong knowledge Of the SAP plant Maintenance integration points to Finance,

Materials Management and project Systems.

• Ability to work in a dynamic environment.

• Ability to work under pressure and meet tight deadlines.

• Good commands Of Oral and Written English,

ROTATING EQUIPMENT ENGINEER JRE26429

• Bachelor’S Degree as minimum in required or related field.

• Minimum 8-10 years Of experience in required technical field,

• Conduct Risk Based Maintenance (RBM) and Root Cause Failure Analysis (RCFA)

for rotating equipment and improve their reliability and availability.

• Communicate With Other Maintenance Divisions and the Department

in to develop and maintain rotating equipment Strategies

• Provide technical expertise for rotating equipment maintenance activities,

standards and procedures. Assist in developing Predictive and Preventative

Maintenance plans and procedures for all rotating equipment

• Administer the performance-monitoring program for rotating equipment

compressor / Pump performance, vibration analysis, themwgraphic surveys and

oil sampling).

• Provide technical assistance and trouble•shooting support for all rotating equiptnent

• Coordinate With the Maintenance Divisions to assist in and predicting

rotating equipment components’ life using appropriate reliability tools, such as

Failure Modes and Effects Analysis (FMéA), Mean time between failures (MTBF) and

Mean Time To Failure (MTTF), to ensure extended operating life of rotating equipment

• Good knowledge of Rotating Equipment functions from maintenance point of view.

• Ability to define maintenance strategies using FMECA and RBM methodologies.

• Good knowledge of rotating equipment, such as compressors, gas,’steam turbines,

and centrifugal pumps

• Good knowledge of rotating equipment performance monitoring, lubrication,

vibration analysis, and sealing systems.

• Ability to continuously drive for process

• Capable of giving strong attention to details

• Strong command of oral and written English.

SENIOR CONTRACTS ENGINEER JRE26428

• Bachelor •s as minimum in required Or related field,

• Minimum 10-12 years of experience in required field

• Lead the respective Contract units comprising Cost Engineer. Contract

Administrator and Quantity to support the administration and

managernent Of general maintenance services. specific maintenance services

and corrective maintenance functions and activities

• Ensure terms and conditlOns are the

scope Of work/ services,

• Review proposed bidders list and / or justification for Single Source. and

proposal criteria are properly established.

• Good knowledge Of Refinery maintenance

• Strong knowledge in Contracts administration,

• Good Contract and preparation Skills,

• Conversant with SAP and Microsoft Office applications.

• Ability to work in a dyi’amic environment, under pressure and meet tight deadlines,

Support Head.

SAP ENGINEER

• Bachelor’s Degree in Engineering,

JRE26430

• Good commands Of oral and written English

CONTRACT SPECIALIST

• Bachelor graduate equivalent.

• Minimu 8 years relevant experience in the same field.

JRE26436

• Minimum g•IO years of experience in required technical field.

• Assist in maintaining SAP system in the Maintenance Department. by supporting

Applicants should submit the following document copies while “Applying Online”

UPDATED CV I EDUCATION CERTIFICATES I PREVIOUS EMPLOYMENT CERTIFICATES I PASSPORT COPY

To applyonline visit: www.jerryvarghese.com/applyonline

Please input the “JRE Code” in the “Quick Search Box” and apply. Select – “Internet / Online”,

Select source -“Facebook” Or Please send your CVs to the mentioned below office “Email Id”

Send your updated CV to: